Technology:

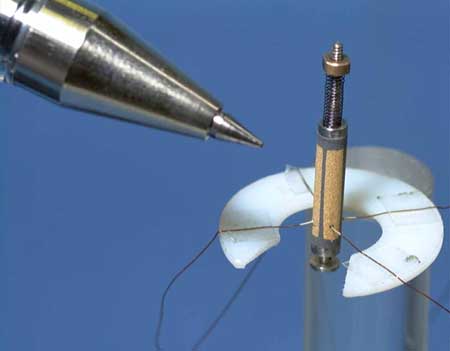

Panasonic developed

a technology of artificial photosynthesis as efficient as a plant. It generates

organic substances from sunlight, water, and carbon dioxide using a system

similar to a solar battery. It employs a self-developed metal catalyst and

gallium nitride used for semiconductors like light emitting diode (LED) for the

system that reacts sunlight, water, and carbon dioxide. It has five times

higher conversion efficiency of organic substances generated by photosynthesis

than the existing technology. Panasonic successfully increased the conversion

efficiency comparable to a plant for the first time in the world. The company

wishes to put the technology into practical use for the synthesis of ethanol in

2015.

Panasonic plans to

build a trial system of artificial photosynthesis that employs a catalyst

similar to a solar panel in terms of shape and open up a way for practical

application of a power generation system using ethanol as fuel generated by

artificial photosynthesis in 2015. Artificial photosynthesis is a very

effective technology for reducing carbon dioxide and solving resource-related

problems, and Japan started a national research project. Dr. Ei-ich Negishi, a

Nobel Prize winner in chemistry in 2010 who is currently teaching at Purdue

University of the U.S., participates in the project organized by the Ministry of Education, Culture, Sports, Science and Technology.

Ei-ichi Negishi Noble Prize Forum 2012

held in Kyushu University

held in Kyushu University