Technology:

Fujitsu developed an

aqueous paint that can be applied to the resin parts of information technology

equipment in alliance with its subsidiary Fujitsu Laboratories. Because moisture

needs to be dried at a high temperature, an aqueous paint is not suitable for application

to resin parts. The company improved the existing aqueous paint to make it

dried at a relatively low temperature. By mixing a fine particle with atwo-layer structure of hard resin and soft resin with pigment, it successfully developedan aqueous resin that can be dried at 65 degrees centigrade. Fujitsu applied

the new aqueous paint to the outer packaging of its servers for the first time,

and plans to increase the number of products in the future.

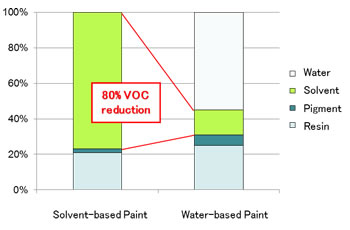

As an oil paint generally

needs to be diluted with such solvents as toluene and xylene, it generates volatile

organic compound (VOC) that causes a photochemical smog. If an oil paint is

replaced by the new aqueous paint, a large amount of solvent for dilution can

be reduced. According to the estimates of the Ministry of Environment, paint is

most responsible for VOC emission, accounting for about 40% of total VOC

emission, in 2010. In the auto industry, lots of efforts are being made to replace

oil paints with aqueous paints to reduce VOC emissions.

Comparison of components

in

solvent-based and water-based paints

No comments:

Post a Comment